Well, where to start, still making parts and running when we can in between school runs, decorating and clearing out some of the junk accumulated in the past 15 years at HQ. The reason for the clear out and sprucing up - besides from th eclear and obvious fact that it neaded it - is here :-

Green Buildings Open Up

Take a look at the website - there is lots of great opportunities to see what you can do with a little motivation and some funds to work with in order to reduce your carbon foot print.

That's all folks - back to the workshop for me.

The Fan-Ce

How an idea is being developed into a micro business.

Thursday 3 October 2013

Friday 27 September 2013

Progress.... of a sort !

As September draws to a close, the new website is all but ready, awaiting a final run through and couple of images - frustrating how getting the right product in use shot takes sooooooo long !

The new Product prototype has been set up and put to the test - initial impressions are good. Air movement is far higher than the Fan-Ce - mainly as a result of the blade set up. Still some work to do to get it market ready.

We took a stroll through YouTube this week and surprise surprise several new videos uploaded on 'How To.. & Buy my Stove Top Fan' with lots looking similar to the Fan-Ce - flattering I guess - but I wonder how serious these 'project are' ?

We continue to scour the used market for Black cooler bodies and whilst the larger series Fan-Ce have been purchased and converted & most sold, the small units remain very similar to rocking horse teeth in terms of availability.

The sun is out, the solar PV is running and I have fire wood to cut, chop & stack and fan parts to make on the lathe.

I leave you with a sample of the product photo's in a 'warm look'

The new Product prototype has been set up and put to the test - initial impressions are good. Air movement is far higher than the Fan-Ce - mainly as a result of the blade set up. Still some work to do to get it market ready.

We took a stroll through YouTube this week and surprise surprise several new videos uploaded on 'How To.. & Buy my Stove Top Fan' with lots looking similar to the Fan-Ce - flattering I guess - but I wonder how serious these 'project are' ?

We continue to scour the used market for Black cooler bodies and whilst the larger series Fan-Ce have been purchased and converted & most sold, the small units remain very similar to rocking horse teeth in terms of availability.

The sun is out, the solar PV is running and I have fire wood to cut, chop & stack and fan parts to make on the lathe.

I leave you with a sample of the product photo's in a 'warm look'

Thursday 19 September 2013

Distractions Come & Go

My life today is full of distractions, in that there are just so many things to take the focus off of what I am 'trying' to do. Every now and then I get the chance or stumble up on, something which actually makes me stop, think and puts me back on track. Last night was a good example.

I attended a networking meeting in the Peak District Dales town of Bakewell, attended by a group of approximately 30 'like minded individuals which share a common interest' - there were a number of speakers myself included - un-prepared as ever ! Always good to catch up with friends made through business.

After the comfort / snack break, I sat and listened to a well written short presentation by a local chap, Paul Cox - he grew up in the village next to mine - Chapel en le Frith in the High Peak, Derbyshire. It was clear he had spent quite some time building up his presentation which was very personal to him.

Paul Cox of Spin Less Plates builds small business software; as a micro business he experiences much the same as I do and many others like us. The thrust of his presentation was (as I suspected he had been asked) to highlight the benefit of a 'Master Mind' approach - that is to say two heads are better than one and 3 than 2 etc etc. All true enough and we could all benefit from fresh perspective and networking with others especially those which a are head of their game. A read once that you can only improve your chess game by getting beaten by a better player.

However, for me Pauls' motivational talk re-focused my own perspective on the WHY do I work for myself doing what I do - it is the question we should all take time out to re-assess.

It is not my intention to put into type my 'WHY' - if for no other reason than my own privacy. Just to say that if I can give one bit of advice to any would be micro-business builders - ask yourself WHY. It makes all the other questions and answers flow far easier.

Talking of distractions, too often these take us further from the WHY on occasion to the point where we have in fact lost track of the WHY and replaced it with a BECAUSE - in an attempt to justify to ourselves at least the fact that we are 'off target'.

Caught up in the 'production of components' earlier in the week and for a brief period having lost track of the WHY as I moved materials around the workshop - my attention was re-focussed by a 'distraction'. Not the kids, or one of the various pets which come to visit the workshop... cats, chickens or dogs. Not one of my retired former work pals. This came in the form of a streak of Blue & Orange with a very long sharp beak and pretty nearly collided with the back of my head. After a few seconds of the poor thing getting lost in the workshop I recovered it from the window ledge and released it outside - it set off as they do with its load SQUEEK and characteristic jet speed back toward the small stream beyond the workshop.

The kingfisher - a bit of a 'Grab Shot' left handed with my mobile phone - still not many can claim to have held such a bird in the UK - protected as it is. Fiesty little thing as well. Stunning colours and quite a few years since I have seen one locally. After a week of running about after others and fitting in production time as and when I could - these simple few seconds of wonder made me re-focus on my WHY.

I have to get out with my Nikon and do more of the things I like; creating new things, solving new challenges - which brings me to a new project for the Stove Fans - watch the blogs for more news soon.

WHY - well because I want to. !

I attended a networking meeting in the Peak District Dales town of Bakewell, attended by a group of approximately 30 'like minded individuals which share a common interest' - there were a number of speakers myself included - un-prepared as ever ! Always good to catch up with friends made through business.

After the comfort / snack break, I sat and listened to a well written short presentation by a local chap, Paul Cox - he grew up in the village next to mine - Chapel en le Frith in the High Peak, Derbyshire. It was clear he had spent quite some time building up his presentation which was very personal to him.

Paul Cox of Spin Less Plates builds small business software; as a micro business he experiences much the same as I do and many others like us. The thrust of his presentation was (as I suspected he had been asked) to highlight the benefit of a 'Master Mind' approach - that is to say two heads are better than one and 3 than 2 etc etc. All true enough and we could all benefit from fresh perspective and networking with others especially those which a are head of their game. A read once that you can only improve your chess game by getting beaten by a better player.

However, for me Pauls' motivational talk re-focused my own perspective on the WHY do I work for myself doing what I do - it is the question we should all take time out to re-assess.

It is not my intention to put into type my 'WHY' - if for no other reason than my own privacy. Just to say that if I can give one bit of advice to any would be micro-business builders - ask yourself WHY. It makes all the other questions and answers flow far easier.

Talking of distractions, too often these take us further from the WHY on occasion to the point where we have in fact lost track of the WHY and replaced it with a BECAUSE - in an attempt to justify to ourselves at least the fact that we are 'off target'.

Caught up in the 'production of components' earlier in the week and for a brief period having lost track of the WHY as I moved materials around the workshop - my attention was re-focussed by a 'distraction'. Not the kids, or one of the various pets which come to visit the workshop... cats, chickens or dogs. Not one of my retired former work pals. This came in the form of a streak of Blue & Orange with a very long sharp beak and pretty nearly collided with the back of my head. After a few seconds of the poor thing getting lost in the workshop I recovered it from the window ledge and released it outside - it set off as they do with its load SQUEEK and characteristic jet speed back toward the small stream beyond the workshop.

The kingfisher - a bit of a 'Grab Shot' left handed with my mobile phone - still not many can claim to have held such a bird in the UK - protected as it is. Fiesty little thing as well. Stunning colours and quite a few years since I have seen one locally. After a week of running about after others and fitting in production time as and when I could - these simple few seconds of wonder made me re-focus on my WHY.

I have to get out with my Nikon and do more of the things I like; creating new things, solving new challenges - which brings me to a new project for the Stove Fans - watch the blogs for more news soon.

WHY - well because I want to. !

Tuesday 3 September 2013

September has arrived and whilst we have built some finished goods stock of all models we will be making up components on the lathes. A shame that the local recycled metal yards have no suitable scrap aluminium to convert - the last of the scrap bar stock was converted in August with good results.

So this morning we took delivery of several hundreds pounds worth of new bar stock - having had the practice on the scrap material - the processing of decent quality material should be fairly straight forward. The main difference is that at 3000mm length & 3600mm I was not going to be able to get this into the workshop and feed it into the saw. The supplier offered two free handling cuts per stock bar. At 1500mm long the half lengths are far easier to maneuver - a few minutes at the saw and each length was cut down to 500mm ready for turning down the diameter to the required size for the fan hubs.

The longer lengths of 76mm diameter bar stock for the base discs still weigh a fair amount and as such will require some considerable care in handling the cutting down to 15mm blank lengths. Every dent on the outer girth requires more machining off to give a clean finish. The heat generated on the band saw without coolant is fine for the initial 15 minutes of cutting after which the stock length is too hot to hold without gloves - slow and steady with two lengths alternating every 10 minutes gets over the issue of heat.

Despite all the handling issues it still works out far more cost effective for the conversion of the bar stock into blanks rather than buying in pre-cut or finished components - the production volumes being in the hundreds rather than the 1000's at this stage to minimize the cash required for the business.

The New Website !

Well work is underway. A little later than I had hoped falling as it does at a a time when the schools start up again and school runs, homework etc etc eat into the available time. I foresee some late nights and weekends playing catch up.

I have in mind to video some of the production work and include sequences on the website and here within this blog to provide a perspective of the micro business ...... just need a digital video camera for a few days ....

Nice to see the existing website interest picking up for the season - sales for Sept' are ahead of Augusts already, encouraging and rewarding to see the investment funds slowly being replaced.

Now where can I get my hands on a Nikon DSLR with video facility ?

So this morning we took delivery of several hundreds pounds worth of new bar stock - having had the practice on the scrap material - the processing of decent quality material should be fairly straight forward. The main difference is that at 3000mm length & 3600mm I was not going to be able to get this into the workshop and feed it into the saw. The supplier offered two free handling cuts per stock bar. At 1500mm long the half lengths are far easier to maneuver - a few minutes at the saw and each length was cut down to 500mm ready for turning down the diameter to the required size for the fan hubs.

The longer lengths of 76mm diameter bar stock for the base discs still weigh a fair amount and as such will require some considerable care in handling the cutting down to 15mm blank lengths. Every dent on the outer girth requires more machining off to give a clean finish. The heat generated on the band saw without coolant is fine for the initial 15 minutes of cutting after which the stock length is too hot to hold without gloves - slow and steady with two lengths alternating every 10 minutes gets over the issue of heat.

Despite all the handling issues it still works out far more cost effective for the conversion of the bar stock into blanks rather than buying in pre-cut or finished components - the production volumes being in the hundreds rather than the 1000's at this stage to minimize the cash required for the business.

The New Website !

Well work is underway. A little later than I had hoped falling as it does at a a time when the schools start up again and school runs, homework etc etc eat into the available time. I foresee some late nights and weekends playing catch up.

I have in mind to video some of the production work and include sequences on the website and here within this blog to provide a perspective of the micro business ...... just need a digital video camera for a few days ....

Nice to see the existing website interest picking up for the season - sales for Sept' are ahead of Augusts already, encouraging and rewarding to see the investment funds slowly being replaced.

Now where can I get my hands on a Nikon DSLR with video facility ?

Thursday 8 August 2013

Getting Ready for the new Season

It is the start of August, the days remain warm and last night was the first one to fall below 10degrees since the 'summer' - a couple of orders have arrived and been fulfilled from the stock.

Dilemma time - How many Fans will we sell this season ?

The Remaining Question - Do we want to carry on with this little project of ours ? We have pretty much resolved the product manufacturing issues and can manufacture far in excess of demand at its expected level. Supply of components has settled down and other than a few 'postage' cost increases the cost base is much as it was.

All in all, "If" sales are as last year, the business will perform well as the fixed overhead costs remain unchanged and the depreciation will be recovered within a further 100 unit sales.

So, we will see how the next season progresses and work on similar volume of sales as last year, having resolved most of the issues encountered last year we can increase output pretty quickly.

In order to make the project a little more 'slick' we have invested in a new website which we hope to have on line in the next 6 weeks. To coincide with this, some new branding and product support (instructions etc) will be brought together.

Stock of the 'Black Krome' variants have been produced all be it in limited numbers - sold on a first come first served basis as last year.

Some further component production required to provide a cushion for any increase in order intake and then it should be a 'smooth' ride to January.

Development of new variants has taken a back seat much of the year as development work was completed to remove production bottle necks, seeing how each added option has increased the stock required we are now looking only to add products for different applications rather than ' premium / economy range etc. As with all things this may change at any time :-)

Dilemma time - How many Fans will we sell this season ?

- The same as last year, more or less ?

- Is the next day service really adding customers or just cost to the business ?

- Do we add to, Reduce or maintain the existing range of products ?

The Remaining Question - Do we want to carry on with this little project of ours ? We have pretty much resolved the product manufacturing issues and can manufacture far in excess of demand at its expected level. Supply of components has settled down and other than a few 'postage' cost increases the cost base is much as it was.

All in all, "If" sales are as last year, the business will perform well as the fixed overhead costs remain unchanged and the depreciation will be recovered within a further 100 unit sales.

So, we will see how the next season progresses and work on similar volume of sales as last year, having resolved most of the issues encountered last year we can increase output pretty quickly.

In order to make the project a little more 'slick' we have invested in a new website which we hope to have on line in the next 6 weeks. To coincide with this, some new branding and product support (instructions etc) will be brought together.

Stock of the 'Black Krome' variants have been produced all be it in limited numbers - sold on a first come first served basis as last year.

Some further component production required to provide a cushion for any increase in order intake and then it should be a 'smooth' ride to January.

Development of new variants has taken a back seat much of the year as development work was completed to remove production bottle necks, seeing how each added option has increased the stock required we are now looking only to add products for different applications rather than ' premium / economy range etc. As with all things this may change at any time :-)

Friday 28 June 2013

Where did the last 6 months go ?

It is now the end of June.

Sales began to slow end of March gave a quick spurt again in April and then steady through May & June ... so seasonal yes but not dropping to zero which is what I had expected come the thaw !

My thoughts have now turned to building stock of the lower cost components in advance of what I hope to see as a busy Autumn / Winter season. The plan being to build the sub-assembly stock and then order the more expensive parts in medium sized batches to complete a minimum stock holding and avoid the delays experienced in the last year. That being said, no orders were cancelled or lost as far as I am aware as a result of my not having stock....but then would I know ?

A couple of developments underway, the first being to get on line with the manufacture of the fan hubs from bar stock and complete the cost reduction of the base production. Both projects involve cutting the bar stock to length prior to turning out the product on my metal lathe.

Having spent a few hrs cutting 3" diameter aluminium bar into 15mm disk blanks for the bases and then hrs cleaning out the swarf from my large vertical bandsaw. I decided to look into the options for alternative methods of cutting the stock. Additional Capital expenditure on new kit was to be avoided as reserves were being held of working capital / stock - low cost used bits of kit were of dubious reliability and borderline scary in use - YouTube research to the rescue - I found video footage of a DIY metal hacksaws big enough for my requirements and small enough for my budget.

The downside of this £60 investment is the huge under estimation of time required to complete the manufacture of the various parts required.... some of which I am still making on the lathe & by hand. That being said, the learning experience has been great and I now have a entire new section of working skills to use words I am unable to put into print for fear of offense. The years I spent hustling a department of engineers to get a move on .... I can only now really appreciate the fact that certain things just take time when its a one off !

Of course the low budget precluded my buying much in the way of new bar stock to size, so the local steel scrap yard has become a new favorite trip - exchanging bags of separated metal swarf for new lumps of rusty metal to convert into more swarf !

The new power hacksaw, is currently awaiting my finishing the vice and then base stand and electric cut off switch . The good thing is that it is already cutting the steel parts from bar stock for me to then turn or file to size etc. Whilst not likely to be faster than the bandsaw, it will be less expensive to run (£1 per blade v's £35 for a start) with its 250w motor instead of the 1750w bandsaw drive - importantly, once set off, it will cut through and then stop without supervision leaving me to work ... well once I finish the electrics' - whereas the bandsaw required my hold the bar stock under pressure against the blade throughout the cut - hot hands (no coolent) and quite hard work after an hour.

This lot will enable me to recover the lost margin from the postage hike by Royal Mail and the international postage for the TEG units, saving as it should best part of a £5 per fan assembly.

Pictures to follow.

But these are the two I like most of all :-

This because it just looks under control, however, getting hold of a suitable reduction gearbox proved troublesome - at £65 plus for a well used 3phase motor an dworm gearbox or lots of work making pulleys etc.

So I went for this, not least because I could buy a set of plans to later ignore !

The chap is quick to reply to email and offers online support. Not one of lifes talkers if the videos are anything to go by. His other videos are very well put together and a good source of 'how to' as have been those from Tubal Cain on all things machine shop. The following video solved a problem for me of cutting very low angle tapers by accident. It was driving me mad .

I have to say, the accent helps soothe the troubles away.

Sales began to slow end of March gave a quick spurt again in April and then steady through May & June ... so seasonal yes but not dropping to zero which is what I had expected come the thaw !

My thoughts have now turned to building stock of the lower cost components in advance of what I hope to see as a busy Autumn / Winter season. The plan being to build the sub-assembly stock and then order the more expensive parts in medium sized batches to complete a minimum stock holding and avoid the delays experienced in the last year. That being said, no orders were cancelled or lost as far as I am aware as a result of my not having stock....but then would I know ?

A couple of developments underway, the first being to get on line with the manufacture of the fan hubs from bar stock and complete the cost reduction of the base production. Both projects involve cutting the bar stock to length prior to turning out the product on my metal lathe.

Having spent a few hrs cutting 3" diameter aluminium bar into 15mm disk blanks for the bases and then hrs cleaning out the swarf from my large vertical bandsaw. I decided to look into the options for alternative methods of cutting the stock. Additional Capital expenditure on new kit was to be avoided as reserves were being held of working capital / stock - low cost used bits of kit were of dubious reliability and borderline scary in use - YouTube research to the rescue - I found video footage of a DIY metal hacksaws big enough for my requirements and small enough for my budget.

The downside of this £60 investment is the huge under estimation of time required to complete the manufacture of the various parts required.... some of which I am still making on the lathe & by hand. That being said, the learning experience has been great and I now have a entire new section of working skills to use words I am unable to put into print for fear of offense. The years I spent hustling a department of engineers to get a move on .... I can only now really appreciate the fact that certain things just take time when its a one off !

Of course the low budget precluded my buying much in the way of new bar stock to size, so the local steel scrap yard has become a new favorite trip - exchanging bags of separated metal swarf for new lumps of rusty metal to convert into more swarf !

The new power hacksaw, is currently awaiting my finishing the vice and then base stand and electric cut off switch . The good thing is that it is already cutting the steel parts from bar stock for me to then turn or file to size etc. Whilst not likely to be faster than the bandsaw, it will be less expensive to run (£1 per blade v's £35 for a start) with its 250w motor instead of the 1750w bandsaw drive - importantly, once set off, it will cut through and then stop without supervision leaving me to work ... well once I finish the electrics' - whereas the bandsaw required my hold the bar stock under pressure against the blade throughout the cut - hot hands (no coolent) and quite hard work after an hour.

This lot will enable me to recover the lost margin from the postage hike by Royal Mail and the international postage for the TEG units, saving as it should best part of a £5 per fan assembly.

Pictures to follow.

But these are the two I like most of all :-

This because it just looks under control, however, getting hold of a suitable reduction gearbox proved troublesome - at £65 plus for a well used 3phase motor an dworm gearbox or lots of work making pulleys etc.

So I went for this, not least because I could buy a set of plans to later ignore !

The chap is quick to reply to email and offers online support. Not one of lifes talkers if the videos are anything to go by. His other videos are very well put together and a good source of 'how to' as have been those from Tubal Cain on all things machine shop. The following video solved a problem for me of cutting very low angle tapers by accident. It was driving me mad .

I have to say, the accent helps soothe the troubles away.

Tuesday 15 January 2013

Jan 2013

Well its getting near to the anniversary of the first trials of my DIY Ecofan (which yes I know is a registered trademark of the nice chaps in Canada full marks for that) - but at the time of my trials I had no idea I would be going into production.

The festive season at the end of 2012 was busy with orders still arriving on the 25th & 26 and over the New Year.

As things stand I am up to date with all orders, but painfully low on stock of the Fan-C, awaiting new supplies next week.

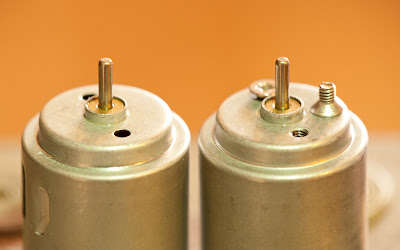

Meanwhile, new supplies of our little drive unit have ...shall we say disappointed: supplied without tapped holes as can be seen in the image below. Whats more is the holes are too large to be tapped out and the case metal too thin to up a size. I am now awaiting news from the supplier to see if he can exchange for the correct units.

As I type, the snow is frozen outside and the workshop a little below freezing point :-) I notice the hens snigger everytime I walk past wrapped up for assembly whilst they sit snug in feather coats !

Website hits continue to roll on with the weekends being most productive, small dips on evenings when the BBC run something new and interesting for a change.

More to follow when I hear from the motor supplier.

Happy New Year, hope you have a good 2013 and thanks for reading this Blog - please leave some comments :-)

Mat.

Well its getting near to the anniversary of the first trials of my DIY Ecofan (which yes I know is a registered trademark of the nice chaps in Canada full marks for that) - but at the time of my trials I had no idea I would be going into production.

The festive season at the end of 2012 was busy with orders still arriving on the 25th & 26 and over the New Year.

As things stand I am up to date with all orders, but painfully low on stock of the Fan-C, awaiting new supplies next week.

Meanwhile, new supplies of our little drive unit have ...shall we say disappointed: supplied without tapped holes as can be seen in the image below. Whats more is the holes are too large to be tapped out and the case metal too thin to up a size. I am now awaiting news from the supplier to see if he can exchange for the correct units.

As I type, the snow is frozen outside and the workshop a little below freezing point :-) I notice the hens snigger everytime I walk past wrapped up for assembly whilst they sit snug in feather coats !

Website hits continue to roll on with the weekends being most productive, small dips on evenings when the BBC run something new and interesting for a change.

More to follow when I hear from the motor supplier.

Happy New Year, hope you have a good 2013 and thanks for reading this Blog - please leave some comments :-)

Mat.

Subscribe to:

Posts (Atom)